Unveiling the Hidden Costs of Recalls in the Life Sciences Industry

The life sciences sector is at public health's forefront and committed to delivering reliable and safe products. However, when a recall is issued, it shakes the very foundation of trust and assurance that companies strive to build. Recalls are more than just a setback; they can be a multidimensional storm of financial loss, public health risks and reputational damage. In this blog post, we will explore the multifaceted costs associated with recalls and discuss how companies can fortify their defenses against these disruptive events.

The Financial Toll of Recalls

Recalls are expensive. They require resources for retrieving and replacing products, investigating the cause and taking measures to prevent future occurrences. The direct costs, such as legal fees and settlements, can be quantified in a company's balance sheet. Yet, the indirect costs, such as lost sales, market share reduction and the intangible blow to brand equity, can ripple through the financial waters for years.

Impact on Public Health

Product recalls in the life sciences industry can ripple through public health systems with severe consequences. The most direct impact is the potential harm to patients, who may experience adverse reactions or, in severe cases, life-threatening health issues due to a defective product. Such events can disrupt critical treatment plans, leading to the progression of diseases or interruption of vital health management. The ensuing loss of confidence in healthcare products can cause patients to delay or refuse necessary treatments, exacerbating health issues.

Recalls also heavily burden healthcare providers, requiring significant time and resources to manage the fallout, from contacting patients to providing alternative treatments. The strain on resources and the increased need for patient monitoring can overwhelm health systems. The psychological stress on affected individuals and increased economic costs can further deteriorate public health. Large-scale recalls especially contamination or vaccines, can also lead to widespread health crises, fueling hesitancy and affecting overall community health. These factors underscore the importance of stringent quality controls and efficient recall protocols to safeguard public well-being.

Reputational Damage

A recall can tarnish a brand's reputation overnight, casting a long shadow over the company's future. In the digital age, where information spreads at lightning speed, the news of a recall can trigger immediate consumer distrust and brand abandonment. The severity and persistence of reputational damage often hinge on the recall's scale and the company's response. A swift, transparent, and effective situation handling can mitigate negative perceptions, while a slow or opaque response can exacerbate them.

Stakeholder perception varies widely: patients may become wary, healthcare providers may switch to alternative brands, investors may reconsider their stakes, and regulatory bodies may impose stricter controls. The ripple effect can extend to the stock market, where a recall might lead to volatile stock prices and shake investor confidence. Furthermore, regulatory aftermath can involve a magnifying glass over the company's practices, sometimes resulting in hefty fines or increased regulatory burdens.

The road to reputational recovery involves an orchestrated effort in crisis management, public relations and stakeholder engagement. Clear communication, empathy and decisive action are the cornerstones of restoring faith in the brand. Ironically, a recall presents a unique opportunity for a company to demonstrate its commitment to consumer safety and its resilience to adversity. Firms that navigate recalls with accountability and foresight can sometimes emerge with a strengthened reputation, viewed as exemplars of responsible stewardship.

The Role of Quality Management Systems (QMS)

A robust QMS is the foundational framework upon which life sciences companies construct their quality assurance and compliance strategies. This comprehensive network of policies, processes and procedures is pivotal in maneuvering the complex and ever-evolving regulatory landscape to maintain product integrity and patient safety. A QMS, however, is not a static entity; its actual robustness is measured by its capacity to adapt to regulatory fluctuations, integrate innovative technological advances and embrace the principles of continuous improvement.

Modern QMS solutions extend beyond compliance. They are crucial in risk assessment and mitigation strategies and help to ensure the organization remains proactive rather than reactive to quality issues. They facilitate a culture where quality is ingrained in every action and decision. Through regular training and involvement, employees become the sentinels of quality, ensuring that the company's commitment to excellence is reflected in every product released on the market.

Incorporating advanced data analytics and software systems enables organizations to transition from traditional record-keeping to dynamic quality intelligence. This shift empowers them to anticipate and preemptively resolve potential issues, make informed decisions based on near real-time data and automate processes for efficiency and reliability. Such systems can also offer predictive insights, transforming how quality is managed and upheld. By integrating these state-of-the-art tools, a QMS becomes a living system that not only helps guard against quality lapses but also propels the company forward in its quest for innovation and excellence. Early detection of an issue can limit the extent of a recall and can prevent it from happening altogether.

Efficient Recall Execution

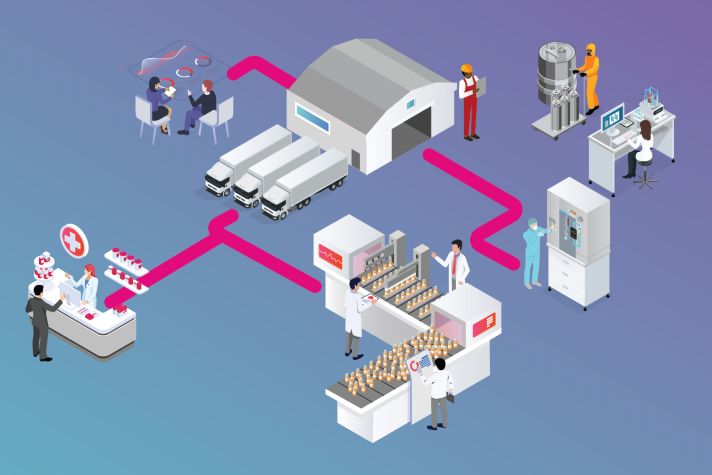

When a recall becomes a necessity, the expediency and efficiency of the response are paramount. Companies must execute recalls with precision, employing well-defined procedures that delineate clear roles across a cross-functional recall team. Effective communication strategies must extend internally to staff and externally to customers, suppliers, and regulatory authorities, maintaining transparency and compliance throughout the process.

Today's technology plays a vital role in streamlining recall management. Automated systems and sophisticated software accelerate the coordination of a recall and enhance traceability and accuracy, ensuring that every affected product is addressed. They can also facilitate direct communication with consumers, providing timely information and instructions, thereby preserving trust and help minimizing confusion and panic.

Conducting regular mock recalls is instrumental in refining a company's recall strategy. These simulations test the readiness and effectiveness of all involved, revealing critical insights into the strengths and vulnerabilities of current practices. This proactive approach allows for continuous improvement of recall procedures, equipping companies with the agility to manage actual events with confidence and minimal disruption.

Harnessing the power of advanced data management, AI and analytics, organizations can now better predict the impact of recalls and implement more strategic risk mitigation plans. By incorporating a lifecycle approach to product quality that includes contingency planning for potential recalls, companies reinforce their commitment to customer safety and position themselves to weather the recall storm with resilience and integrity.

Harnessing Recall Solutions for Industry Resilience

The actual cost of a recall is more than just a line item in a budget; it encompasses the well-being of patients and the trust of customers. While a resilient QMS is indispensable, proactive detection and preparedness for efficient recall execution are equally vital. By leveraging technology and fostering a culture of continuous improvement, life sciences companies can navigate the choppy waters of recalls, ensuring their commitment to patient safety and product reliability remains unshaken.

In a realm where precision and reliability are expected and required, a proactive approach to quality management is more than merely an operational choice. It's a strategic imperative for survival and success.